In a important shift within the manufacturing landscape, HydroBlok, a leading innovator in the outdoor and recreational products sector, has announced plans to relocate its manufacturing operations from Asia to Utah. This strategic decision is poised to enhance production efficiencies while bolstering local job opportunities in a region known for its robust industrial base. As businesses increasingly seek to minimize supply chain vulnerabilities and adapt to changing market dynamics, HydroBlok’s move underscores a broader trend of reshoring manufacturing to the United states.The company’s transition reflects its commitment to sustainability and quality, aligning with the growing demand for domestically produced goods. This article delves into the implications of HydroBlok’s relocation, exploring potential economic impacts, community responses, and the future of manufacturing in Utah.

HydroBlok’s Strategic Shift: Understanding the Move from Asia to Utah

HydroBlok’s decision to relocate its manufacturing operations from Asia to Utah marks a significant strategic pivot aimed at optimizing supply chain efficiency and reducing lead times. by moving closer to its key market in the United States, the company is poised to benefit from enhanced responsiveness to customer demand and market trends. This shift not only streamlines production but also fosters a more sustainable operational model. The move is expected to create job opportunities in the local community, stimulating the economy and promoting regional growth.

One of the primary drivers behind this transition is the increasing cost pressures associated with overseas manufacturing, including rising labor and shipping expenses. By establishing its new facility in Utah, HydroBlok can leverage a skilled workforce and take advantage of the region’s robust infrastructure. Additionally, the benefits of shorter transportation routes support the company’s commitment to sustainability. Key advantages of the move include:

- Cost Efficiency: Reducing logistics expenses by localizing production.

- Market Accessibility: Increased ability to respond to consumer needs and product changes.

- Job Creation: Contributions to employment and economic growth in Utah.

Economic Implications for Local Communities in utah

The decision by HydroBlok to move its manufacturing operations from Asia to utah heralds several economic benefits for local communities. This transition promises an increase in job opportunities, particularly in the manufacturing sector, which has seen fluctuations in recent years. A shift like this can result in a more stable employment landscape and greater workforce engagement. Notably, the following impacts could be observed:

- Job Creation: New positions will be available, allowing local residents to leverage their skills and contribute to the economy.

- Increased Local Spending: As employees gain employment, their disposable income will boost local businesses.

- Infrastructure Development: With more operations,there might be upgrades in local infrastructure,benefiting the community as a whole.

Furthermore, the environmental and sustainability considerations tied to this move could foster new industries in the area, such as green technology. Local suppliers will stand to benefit from enhanced business opportunities, creating a robust supply chain ecosystem. This is indicative of a broader trend in reshoring manufacturing operations, where communities might see an influx in related support services such as logistics and maintenance. Below is a summary of potential economic shifts:

| Economic Aspect | Potential Impact |

|---|---|

| Job Growth | Increased employment and lower unemployment rates |

| Community Spending | Boost in revenue for local businesses and services |

| Supplier Opportunities | Growth for local suppliers and ancillary industries |

| Environmental Strategies | Potential for innovation and new business models |

Evaluating the Supply Chain Benefits of Domestic Manufacturing

As HydroBlok transitions its manufacturing operations from Asia to Utah, the potential supply chain benefits become increasingly apparent. By relocating production closer to its primary market, the company can significantly reduce lead times, allowing for quicker response to consumer demands. This strategic move not only enhances adaptability but also improves the reliability of product availability, minimizing the disruptions often seen with overseas shipping. The immediate availability of materials and components fosters a more efficient production cycle, ultimately resulting in better customer satisfaction.

Additionally, domestic manufacturing can lead to notable cost savings in the long term. While initial investments in local facilities may seem high, the reduction in shipping costs, tariffs, and logistics complexity can quickly outweigh these expenses. HydroBlok’s decision may generate a ripple effect in local economies by creating jobs and supporting local suppliers, further solidifying its position within the community. the advantages of a restructured supply chain can be summed up in the table below:

| benefit | description |

|---|---|

| Reduced Lead Times | Faster delivery times to customers. |

| Cost Efficiency | Lower shipping and logistical costs. |

| Local Economic Impact | Job creation and support for local suppliers. |

| Increased Flexibility | Ability to adjust production based on market demand. |

Workforce Development: Preparing for New job Opportunities

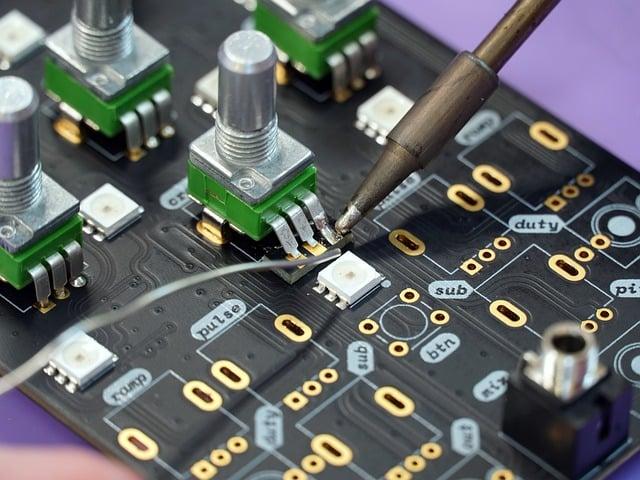

As HydroBlok transitions its manufacturing operations from asia to Utah, this strategic move not only enhances the company’s logistical efficiency but also opens up a myriad of new job opportunities for the local workforce. The relocation aims to harness the talent and skills of residents,ensuring that employees can engage in cutting-edge manufacturing processes.Key sectors poised for growth include:

- Manufacturing Engineering: Positions focused on optimizing production efficiency.

- Quality Control: Essential roles that ensure product integrity and safety standards.

- Logistics Management: Professionals responsible for the supply chain and distribution networks.

- Skilled Labor: Technicians and assemblers who are integral to the manufacturing process.

This influx of job opportunities necessitates a robust workforce development strategy aimed at equipping individuals with the necessary skills to thrive in these roles. Local educational institutions and training programs are pivotal in this undertaking, focusing on:

- Technical Training: Hands-on programs that build competency in manufacturing technologies.

- Apprenticeships: Partnerships with HydroBlok for practical experience in a corporate setting.

- Soft Skills Development: Emphasizing teamwork,communication,and problem-solving abilities.

See below for a simple overview of the types of training being implemented:

| Program Type | Description | Duration |

|---|---|---|

| Technical Training | Focus on machinery and production processes | 6-12 months |

| Apprenticeships | Hands-on learning with HydroBlok professionals | 12-24 months |

| Soft skills Workshops | Enhancing workplace communication and collaboration | 3 months |

Environmental Impact of Manufacturing Relocation

The relocation of manufacturing operations from Asia to Utah by HydroBlok marks a significant shift in the environmental landscape of the production sector. By moving closer to its consumer base and utilizing local resources,HydroBlok aims to reduce the carbon footprint associated with long-distance transportation. This transition is expected to lead to a decrease in greenhouse gas emissions, which can be attributed to several factors:

- shortened Supply Chains: Local manufacturing minimizes shipping distances, resulting in lower transportation emissions.

- Energy Efficiency: Utah’s cleaner energy sources can lead to improved sustainability in production processes.

- Waste Reduction: Utilizing advanced technologies in local plants can optimize resource use and reduce waste.

However, the environmental implications extend beyond emission reductions.The shift also brings attention to natural resource management and regional biodiversity. With manufacturing operations based in Utah, HydroBlok has the opportunity to implement eco-pleasant practices that protect local ecosystems. Key considerations include:

| Aspect | Potential Impact |

|---|---|

| Water Usage | Responsible sourcing and usage can prevent local water depletion. |

| Land Use | careful site selection can mitigate habitat disruption and promote conservation. |

| Materials Sourcing | Choosing sustainable materials can enhance overall environmental benefits. |

Future Growth Prospects for HydroBlok and the utah Economy

the decision by HydroBlok to relocate its manufacturing operations to Utah signifies a promising shift not only for the company but also for the broader economy of the region. As the demand for sustainable building materials continues to rise,HydroBlok is positioned to leverage Utah’s strategic advantages.These include an ideal logistics network, access to a skilled workforce, and a robust infrastructure that supports the expansion of manufacturing capabilities. With plans to hire more local employees, the initiative is expected to create numerous job opportunities in the manufacturing sector, thus contributing to an uptick in economic activity across the state.

Moreover, this move aligns with Utah’s commitment to fostering innovation and supporting businesses that prioritize sustainability. HydroBlok’s advanced, eco-friendly technology will likely attract attention from investors and potential partners, reinforcing Utah’s reputation as a hub for green technology. The ripple effect of this transition could stimulate growth in various sectors,including construction,transportation,and retail. To illustrate the projected impact on the state’s economy, the table below highlights key economic indicators anticipated to benefit from HydroBlok’s relocation:

| Indicator | Current State | Projected Growth |

|---|---|---|

| Job Creation | 1,000 | 1,500+ |

| Investment in R&D | $2 million | $5 million |

| Revenue Generation | $10 million | $20 million |

The way Forward

HydroBlok’s strategic decision to relocate its manufacturing operations from Asia to Utah marks a significant shift in the landscape of American manufacturing. As the company seeks to enhance operational efficiency and support local economies, this move not only aligns with the growing trend of reshoring but also highlights the potential for innovation within the region. With the promise of job creation and economic investment, Utah stands to benefit greatly from HydroBlok’s commitment to maintaining quality production closer to home. As industries continue to navigate the complexities of global supply chains, this development serves as a timely reminder of the importance of adaptability in today’s economic climate. KSL.com will continue to monitor the impacts of this transition,providing updates on how HydroBlok’s operations shape the local workforce and economy in the months to come.