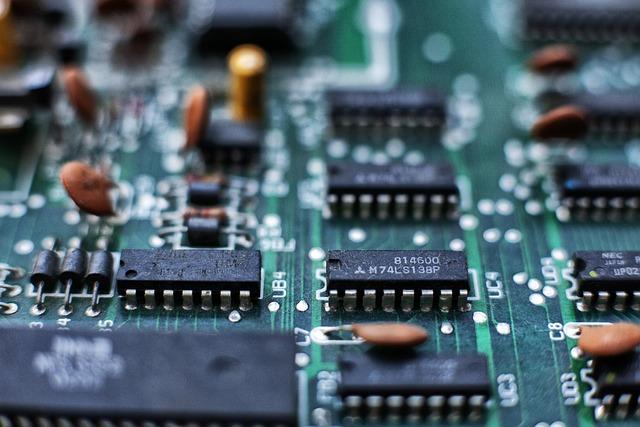

In a rapidly evolving global semiconductor landscape, major players like TSMC, Intel, and other leading chip manufacturers are reassessing their expansion plans in key markets such as Japan and Malaysia. A recent report from Nikkei Asia highlights a shift in strategy, as these industry giants navigate challenges ranging from supply chain disruptions to geopolitical tensions. This article delves into the implications of these slowed expansions on the semiconductor market, the broader technology ecosystem, and the economies of the regions involved, providing insights into how these developments will shape the future of chip production and innovation worldwide.

Impact of Global Chip Demand on Expansion Strategies of TSMC and Intel

The recent surge in global chip demand has led to meaningful shifts in the expansion strategies of major semiconductor players like TSMC and Intel. Both companies are carefully reassessing their plans in the wake of fluctuating market dynamics and geopolitical considerations. As companies strive to balance production capacity with supply chain stability, the emphasis is shifting from aggressive expansions in regions like Japan and Malaysia to a more cautious and strategic approach. this recalibration underscores not only the volatility in demand but also the need for adaptability in a sector where innovation cycles can rapidly change priorities.

Factors influencing these decisions include:

- Supply chain disruptions: Ongoing geopolitical tensions have made companies rethink their dependency on specific regions for manufacturing.

- Investment allocations: Companies are likely focusing resources on enhancing existing facilities rather than committing to new sites.

- technological advancements: The need for cutting-edge technology to meet evolving consumer demands is forcing companies to invest heavily in R&D rather than expansion.

As a result, TSMC’s and Intel’s current strategies may focus more on optimizing operational efficiencies and integrating lean manufacturing processes rather than expanding their geographic footprints. This interior-focused approach allows them to respond quickly to market demands while minimizing the risks associated with overseas investments.

Japan and Malaysia’s Role in the Semiconductor Supply Chain Landscape

Japan and Malaysia have long been pivotal players in the global semiconductor supply chain, but recent developments indicate a potential slowdown in their respective roles. both nations have attracted significant investments from major semiconductor manufacturers, including TSMC and Intel, aiming to bolster local production capabilities. However, challenges such as supply chain disruptions, rising operational costs, and geopolitical tensions have prompted these companies to reevaluate their expansion strategies, leading to delays in planned projects and investments.

Despite these challenges,Japan and Malaysia remain integral to the semiconductor landscape due to their strategic advantages. Key factors contributing to their importance include:

- Japan: A robust ecosystem of advanced manufacturing technologies, skilled workforce, and a strong emphasis on research and growth.

- Malaysia: Competitive labor costs, existing infrastructure for electronics manufacturing, and favorable trade agreements.

These dynamics, coupled with an increasing demand for semiconductors globally, suggest that while expansions might potentially be momentarily slowed, the fundamental role that Japan and Malaysia play in the semiconductor supply chain remains significant and vital for the industry’s future.

Economic Implications of Slower Expansion for Regional Manufacturers

The decision by major chip manufacturers, including TSMC and Intel, to slow their expansion in Japan and Malaysia carries significant economic implications for regional manufacturers. Supply chain disruptions, already exacerbated by geopolitical tensions, are likely to further impact these manufacturers who rely on chips for production. The reduction in new facilities and capital investment leads to a decreased supply of semiconductors, which in turn affects everything from consumer electronics to automotive manufacturing. As production capabilities dwindle, manufacturers may face challenges in meeting consumer demand, possibly leading to increased prices and longer lead times.

Moreover, the slowdown in expansion can hinder technology transfer and innovation, which are critical for manufacturers aiming to keep pace with global competition. Local businesses may find themselves at a competitive disadvantage, as larger firms scale back investments in automation and advanced manufacturing techniques. This stagnation could result in the following outcomes:

- Increased unemployment rates</ as firms adjust to reduced production abilities.

- Lower investment in R&D due to decreased revenues from slower growth.

- Economic stagnation across regions heavily reliant on manufacturing.

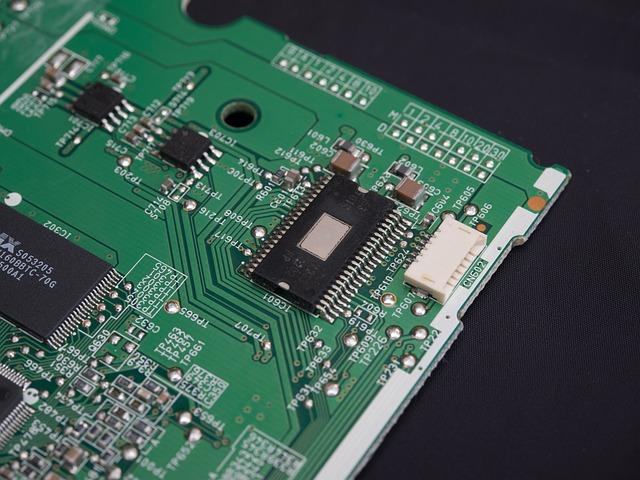

Technological advancements Driving Changes in Chip Production

The semiconductor industry is undergoing a transformative phase, largely propelled by rapid technological advancements that redefine chip production processes. With giants like TSMC and Intel navigating complex global supply chains, the focus has shifted towards incorporating next-generation technologies to enhance efficiency and productivity. Innovations such as Extreme Ultraviolet (EUV) lithography, 3D chip stacking, and AI-driven manufacturing systems are at the forefront, streamlining the production pipeline. These technologies not only reduce the time taken to manufacture chips but also enable the production of smaller, more powerful semiconductors that meet the increasing demands of a tech-driven world.

Despite significant progress, recent decisions by major chipmakers to slow expansions in countries like Japan and malaysia highlight the industry’s delicate balance between rapid advancement and strategic caution. The primary factors influencing these measured approaches include fluctuating demand, geopolitical tensions, and investments in sustainability. As companies reassess their growth strategies, they are weighing the benefits of localization against the need for scalability. The current landscape reflects a transition where manufacturers must adapt to not only deliver cutting-edge technology but also navigate the complexities of a global market that is ever-evolving.

| Company | Recent Expansion Decision | Key Technology Focus |

|---|---|---|

| TSMC | Slowed investments in Japan | EUV lithography |

| Intel | Paused expansion in Malaysia | 3D chip stacking |

| Samsung | Restructured expansion strategy globally | AI-driven manufacturing |

Strategic Recommendations for Semiconductor Investment in Asia

The semiconductor industry is at a pivotal juncture, particularly in Asian markets like Japan and Malaysia where leading companies such as TSMC and Intel are reassessing their expansion strategies. To navigate this dynamic landscape effectively, stakeholders should consider the following strategic recommendations for investment:

- diversification of Supply Chains: Expand partnerships with local suppliers and manufacturers to mitigate risks associated with global supply chain disruptions.

- Investment in R&D: Allocate resources towards research and development to foster innovation in chip designs that cater to emerging technologies like AI and IoT.

- Government Collaboration: Engage with local governments to leverage incentives and support programs aimed at boosting semiconductor manufacturing.

Moreover, it is indeed essential to monitor market trends and consumer demand shifts to make informed investment decisions. The following table outlines key factors influencing semiconductor investments in asia:

| Factor | Impact on Investment |

|---|---|

| Technological Advancements | Increased demand for cutting-edge chips, driving investments in R&D and production. |

| Geopolitical Considerations | Heightened scrutiny and regulation may influence site selection and operations. |

| Environmental Regulations | Investment required to comply with sustainability standards and reduce carbon footprint. |

in summary

the strategic pause in expansion activities by leading semiconductor manufacturers, including TSMC and Intel, in regions like Japan and Malaysia underscores the complexities of the global chip market. As these companies navigate a landscape shaped by supply chain challenges, geopolitical tensions, and fluctuations in demand, their decisions reflect a cautious approach to future investments.this development not only highlights the delicate balance these firms must maintain in their growth strategies but also emphasizes the critical importance of regional manufacturing capabilities in an increasingly competitive industry. Moving forward, stakeholders will be keenly watching how these dynamics evolve and what implications they hold for the broader semiconductor ecosystem. The future of chip production remains uncertain, but the choices made by these industry giants will undoubtedly have lasting effects on technological advancement and economic stability in Asia and beyond.