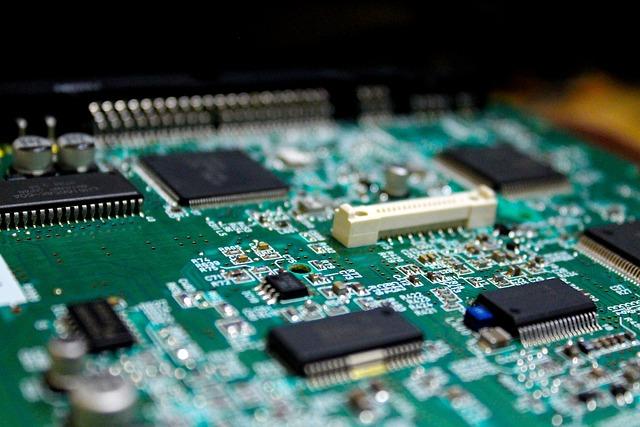

In a meaningful progress within the semiconductor supply chain, YEST has entered discussions with Japan’s Kioxia regarding the provision of High Purity Aluminum (HPA) kits. This collaboration could mark a pivotal moment in enhancing the sustainability and efficiency of semiconductor manufacturing processes. As global demand for advanced chips continues to surge, the partnership aims to leverage YEST’s innovative HPA technologies to bolster kioxia’s operations. The talks come at a time when securing high-quality materials is critical for producers looking to maintain competitive advantage amidst growing industry pressures. This article delves into the implications of this potential partnership and what it means for both companies, as well as the broader semiconductor landscape.

YEST and kioxia Explore Partnership for HPA Kit Supply

In a move aimed at bolstering their product offerings, the collaboration between YEST and Kioxia is poised to innovate the realm of High Purity Ammonia (HPA) kits.This partnership leverages Kioxia’s extensive expertise in semiconductor technology, combined with YEST’s capabilities in HPA production. Both companies view this joint venture as a strategic step towards enhancing supply chain efficiency and meeting the growing demand for high-quality materials in the semiconductor industry.

The partnership’s focus includes the following key areas:

- Technology Exchange: Facilitating knowledge transfer to enhance product quality.

- Supply Chain Integration: Streamlining logistics to ensure timely delivery of HPA kits.

- Market Expansion: Jointly exploring opportunities in emerging markets.

As the semiconductor market continues to expand, YEST and Kioxia’s partnership could set a benchmark for future collaborations in the industry, positioning both companies at the forefront of HPA technology and supply.

Implications of the Collaboration on the Semiconductor Industry

The recent collaboration between YEST and Japan’s kioxia is poised to substantially impact the semiconductor industry. By supplying HPA (High-Purity Aluminum) kits, this partnership may lead to advancements in semiconductor manufacturing processes. The use of HPA can enhance the performance and reliability of semiconductor devices, enabling the production of more efficient and powerful technology. As demand for semiconductors escalates globally, strategic collaborations such as this could streamline the supply chain and foster innovation, directly addressing the needs of various tech sectors including consumer electronics, automotive, and data centers.

Moreover, this alliance not only enhances the competitive landscape of the semiconductor market but also reflects a broader trend of cross-industry partnerships aimed at increasing production resilience.The implications for local economies and job markets could be substantial, as companies invest in new technologies and manufacturing capabilities. Key benefits of this collaboration may include:

- Improved efficiency: Optimizing manufacturing through advanced materials.

- Enhanced product quality: HPA kits can lead to better-performing semiconductors.

- Industry growth: Strengthening supply chains and driving expansions in production.

Technological Advancements in High-Purity Alumina Kits

recent developments in high-purity alumina (HPA) technology are set to revolutionize multiple industries, especially in the realms of battery manufacturing and electronic components. The collaboration between YEST and Japan’s Kioxia exemplifies the growing emphasis on advanced materials that enable increased efficiency and performance. HPA kits provide a highly refined and pure aluminum oxide, which is critical for ensuring superior product quality in applications such as LED lighting, electronics, and lithium-ion batteries.

Key benefits of high-purity alumina kits include:

- Enhanced Purity: Minimizes impurities that can affect performance.

- Improved Stability: Offers greater stability under extreme conditions.

- Environmentally Friendly: Reduces reliance on hazardous materials.

- scalability: Adaptable to varying production needs, fitting both small and large-scale operations.

With the growing demand for eco-friendly and high-performance materials, the importance of such innovations cannot be overstated. As global markets shift towards sustainability, the advancements in HPA technology are likely to play a pivotal role in shaping future material science and manufacturing practices.

Market Dynamics: YEST’s Position in Global Supply Chains

The strategic discussions between YEST and Kioxia mark a significant movement in the global supply chain dynamics, particularly in the high-performance materials sector. With the demand for High Purity Aluminum (HPA) kits surging due to advancements in semiconductor technology and the electronics industry, YEST’s collaboration with a major player like Kioxia positions it favorably within an increasingly competitive landscape. The expected partnership is set to not only enhance operational synergies but also streamline the sourcing and supply of critically needed materials, thereby reinforcing both companies’ foothold in international markets.

As companies worldwide navigate the complexities of supply chain disruptions and raw material shortages, YEST is keenly aware of its role in ensuring stability and reliability. By aligning with Kioxia, YEST can capitalize on opportunities to strengthen its market presence and improve its procurement capabilities. Key advantages of this partnership could include:

- Access to Cutting-Edge Technology: Leveraging Kioxia’s innovations in semiconductor manufacturing.

- Enhanced Production Efficiency: Streamlining processes to reduce lead times for HPA kit delivery.

- Market Expansion: Penetrating new markets by utilizing Kioxia’s established distribution networks.

| Aspect | YEST | Kioxia |

|---|---|---|

| Market Focus | High Purity Aluminum Kits | Semiconductor Manufacturing |

| Geographic Reach | Emerging Markets | Global |

| Supply Chain Position | Material Supplier | End Manufacturer |

Strategic Recommendations for Stakeholders in the Semiconductor Sector

As the semiconductor industry faces increasing demand for advanced technologies, stakeholders must adopt a proactive approach to navigate the evolving landscape. Collaboration between manufacturers and suppliers will be crucial, particularly considering YEST’s strategic discussions with Kioxia. By fostering strong partnerships, stakeholders can enhance their supply chain resilience. Equally significant is investing in research and development to innovate and improve existing processes. This emphasis on technological advancement will not only boost productivity but also mitigate the risks associated with supply shortages and geopolitical uncertainties.

To maximize competitiveness in this sector, stakeholders should consider the following strategic actions:

- Diversify Supply Chains: Reduce dependency on a single source by exploring additional suppliers and alternative technologies.

- Leverage Emerging Markets: Identify and tap into new markets to expand product reach and reduce the impact of regional limitations.

- Implement Sustainability Practices: Commit to environmentally responsible manufacturing processes to meet regulatory requirements and appeal to environmentally conscious consumers.

With these strategies in place, companies can better position themselves in the semiconductor market and ensure long-term growth. Here’s a brief overview of potential areas for innovation:

| Innovation Area | Potential Impact |

|---|---|

| Next-Generation Materials | Enhanced performance and efficiency |

| AI Integration | Improved production forecasting |

| Smart Manufacturing | Reduced operational costs and increased productivity |

Future Outlook: Potential Impacts of HPA Innovations on Electronics

The collaboration between YEST and Kioxia to supply High Purity Alumina (HPA) kits stands to reshape the landscape of the electronics industry. As the demand for advanced materials intensifies with the rapid evolution of tech, particularly in semiconductors, the adoption of HPA could lead to transformative changes. This strategic partnership is set to not only enhance the quality of electronic components but also improve the sustainability of manufacturing processes. The following outcomes are anticipated:

- Increased Efficiency: HPA’s superior properties could lead to reduced energy consumption during production.

- Enhanced Device Performance: The use of HPA in semiconductor manufacturing can improve thermal stability and prolong durability.

- Sustainability: With a focus on eco-friendly processes, HPA offers a greener alternative that aligns with global environmental goals.

Furthermore, the potential impacts of HPA innovations extend beyond basic production enhancements. As electronics become ever more integral to daily life, the scalability of HPA technologies could facilitate the development of next-generation products.Notably, advancements could see:

| Impact Area | Potential Outcomes |

|---|---|

| Miniaturization | Smaller, more compact devices with increased functionality. |

| Cost Reduction | Lower production costs through enhanced material efficiency. |

| Market Expansion | New applications in fields such as consumer electronics and aerospace. |

To Conclude

YEST’s ongoing negotiations with Japan’s Kioxia highlight a significant step forward in the semiconductor supply chain, particularly in the realm of High Purity Aluminum (HPA) kits. As demand for advanced memory solutions continues to rise, the collaboration could pave the way for enhanced production capabilities and technological advancements in the industry. Both companies stand to benefit from this partnership, potentially streamlining operations and increasing efficiency in semiconductor manufacturing. The outcome of these discussions may not only impact YEST and Kioxia, but also the broader landscape of the global semiconductor market, as they seek to align their resources to meet the growing needs of the digital economy. Stakeholders will be keenly watching these developments as they unfold.