Bittele Expands global Footprint with PCB Assembly Capabilities in Malaysia

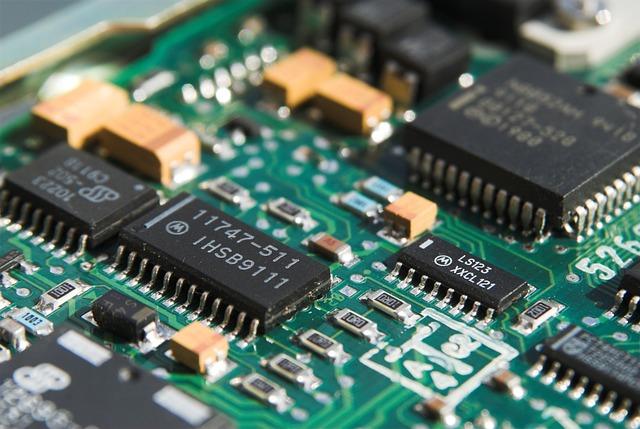

In a meaningful move that underscores the growing demand for advanced electronics manufacturing, Bittele Electronics has announced the launch of its new printed circuit board (PCB) assembly capabilities in Malaysia. This expansion marks a pivotal moment for the company, positioning it strategically within Southeast Asia’s thriving tech ecosystem. With this facility, Bittele aims to enhance its operational efficiency, reduce lead times, and deliver high-quality PCB assembly services to clients across diverse industries. The decision to invest in Malaysia reflects the region’s robust infrastructure,skilled workforce,and favorable business surroundings,aligning perfectly with Bittele’s commitment to innovation and customer satisfaction. This article explores the implications of Bittele’s expansion, the benefits it brings to the local market, and the potential impact on the global electronics supply chain.

Bittele’s Strategic Expansion into Malaysia’s PCB Assembly Market

Bittele’s move to establish PCB assembly capabilities in Malaysia is a bold step that reflects its commitment to addressing the growing demand for high-quality electronic components in the region. This expansion is set to not only enhance the company’s operational capacity but also optimize the supply chain for existing and new clients. With a strategic location in Southeast Asia, Malaysia serves as a gateway to various markets, allowing Bittele to deliver shorter lead times and improved logistics for both domestic and international customers.

The state-of-the-art facility in Malaysia will enable Bittele to offer a extensive range of PCB assembly services that cater to various industries, including automotive, healthcare, and consumer electronics. Key features of this expansion include:

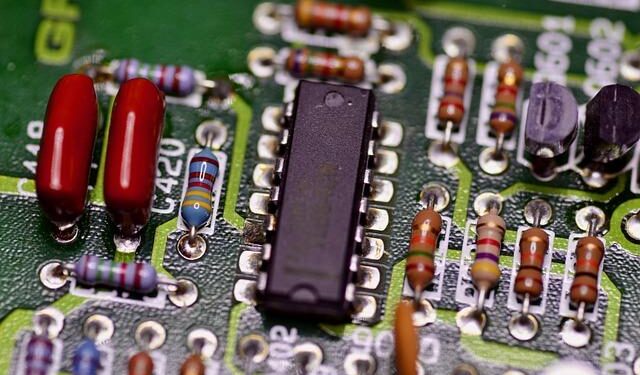

- Advanced Technology: Adoption of cutting-edge machinery and process automation.

- Skilled workforce: Collaboration with local talent to ensure high-quality standards.

- Sustainability Initiatives: Commitment to environmentally responsible manufacturing practices.

To provide a clearer picture of the advantages gained from this expansion, here’s a simple overview:

| Benefits | Description |

|---|---|

| Reduced Lead Times | Faster turnaround for local and regional clients. |

| Cost Efficiency | Lower transportation costs and competitive pricing. |

| Market accessibility | Improved access to emerging markets in Asia. |

Local Economic Impact of Bittele’s New PCB Assembly Facility

The establishment of the new PCB assembly facility by Bittele in Malaysia is set to bring significant benefits to the local economy. This investment not only enhances the country’s position as a hub for electronics manufacturing but also creates numerous job opportunities for the region. The facility is expected to generate a ripple effect across various sectors, with potential collaborations between local suppliers and businesses. The integration of advanced technology will elevate the skill set of the workforce and provide invaluable training that equips employees for future challenges in the industry.

Moreover, the influx of foreign investment fosters a competitive environment that may lead to lower production costs and improved product quality in the electronics sector. This growth could stimulate local entrepreneurship as small and medium enterprises (SMEs) capitalize on the demand for services related to PCB assembly and manufacturing. Consequently, the growth projections for the surrounding areas include:

- Increased employment rates: Direct employment opportunities within the facility and indirect jobs in the local community.

- Boost in local suppliers: Enhanced business for local vendors providing materials and services.

- Economic diversification: Expansion beyond conventional industries into high-tech sectors.

Enhancing Supply Chain efficiency through Malaysia’s PCB Services

With the growth of technology and the increasing sophistication of electronic devices, Malaysia’s PCB services are becoming invaluable in optimizing supply chain operations. Companies can leverage the country’s strategic geographical position, which allows for faster shipping routes throughout Asia and the Pacific, reducing lead times and enhancing responsiveness to market demands. This geographical advantage is complemented by a skilled workforce adept in the nuances of PCB assembly and manufacturing, ensuring high-quality outputs that meet international standards.

By utilizing sophisticated manufacturing processes and state-of-the-art equipment, local PCB service providers can offer a range of capabilities that directly contribute to supply chain efficiency. Key benefits include:

- Rapid Prototyping: Accelerate product development cycles.

- Cost-Effective Solutions: Minimize production costs through local sourcing.

- Flexible Manufacturing: Adapt to changes in order volumes and designs with ease.

- Quality Assurance: Ensure reliability and consistency through rigorous testing.

Moreover, the collaboration between PCB manufacturers and electronic companies facilitates streamlined dialog and project management. consider the following advantages of integrating PCB services within the supply chain framework:

| Advantage | Description |

|---|---|

| Increased Adaptability | Ability to pivot based on demand changes without significant disruptions. |

| Local Partnerships | Enhanced collaboration with suppliers leads to better innovation. |

| R&D Support | Access to advanced research and development capabilities fosters innovation. |

Technical Advantages of Bittele’s Assembly Solutions in Malaysia

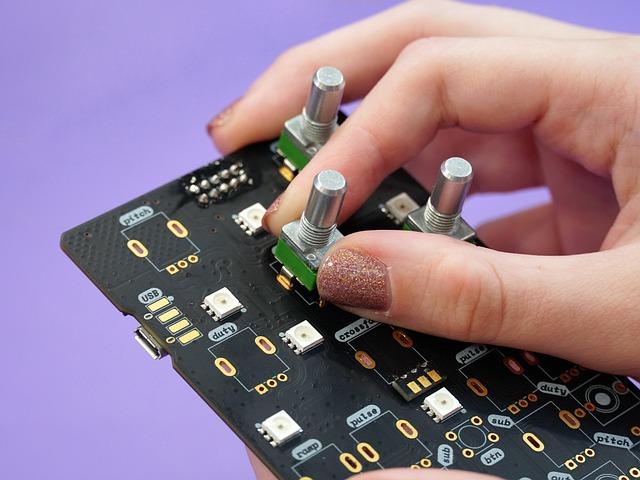

Bittele’s assembly solutions in Malaysia leverage cutting-edge technology to ensure high-efficiency manufacturing processes. Advanced machinery and state-of-the-art techniques are utilized to enhance productivity and precision, which results in faster turnaround times while maintaining stringent quality standards. These capabilities are pivotal for businesses looking for reliable suppliers to meet their electronic assembly needs. Significant features include:

- High-Precision Pick and Place Machines: Designed for accuracy, these machines minimize misalignment and improve overall assembly speed.

- Automated Inspection systems: Essential for quality control, these systems detect defects early, reducing waste and rework costs.

- Environmentally-friendly Practices: Bittele adopts lasting manufacturing processes that comply with international environmental regulations.

The integration of these technologies not only streamlines manufacturing but also enhances capability in producing complex PCBs. With rapid prototyping and a flexible production line,clients can benefit from customized solutions tailored to their specific project requirements. Moreover,a dedicated support team ensures seamless communication and operational transparency throughout the assembly process. Key advantages of Bittele’s solutions include:

| Feature | Benefit |

|---|---|

| Scalability | Easily adapt to changing production demands |

| Cost-Effective Solutions | Reduce overall manufacturing costs with efficient processes |

| Rapid Turnaround | Meet tight deadlines without compromising quality |

Recommendations for Electronics Firms Collaborating with Bittele

As electronics firms consider partnerships with Bittele following their recent expansion into Malaysia, several strategic recommendations can definitely help enhance collaboration outcomes. First and foremost, firms should leverage Bittele’s local expertise to navigate the Southeast Asian market effectively. This includes understanding regional trends,customer preferences,and regulatory frameworks.Engaging in regular communication with Bittele’s team will ensure that project milestones are met while fostering a collaborative spirit that drives innovation and efficiency.

Additionally, electronics companies should align their product development timelines with Bittele’s assembly capabilities to streamline processes. Here are some suggested steps to achieve this:

- Conduct joint planning sessions to synchronize R&D and manufacturing schedules.

- Share detailed specifications and prototypes early in the process to mitigate potential delays.

- Establish clear metrics for success that both parties can monitor throughout the collaboration.

Furthermore, utilizing Bittele’s robust technological resources and tools can substantially improve time-to-market for new products. Creating a partnership agreement that outlines shared objectives and expectations will pave the way for mutual success.

Future Trends in PCB Assembly and Bittele’s Role in Southeast Asia

The electronics industry is witnessing a significant shift towards advanced technologies in PCB assembly, driven by the increasing demand for miniaturization and automation. This trend emphasizes the necessity for companies to adopt state-of-the-art processes such as surface mount technology (SMT), through-hole technology, and automated optical inspection (AOI). As Southeast Asia becomes a hub for electronics manufacturing, organizations like Bittele are stepping up to meet the evolving needs of this dynamic market. With new capabilities established in Malaysia, Bittele is poised to enhance its service offerings, providing clients with cutting-edge solutions that ensure high quality, efficiency, and precision in production.

Strategically located in Malaysia, Bittele aims to leverage the country’s skilled workforce and favorable business environment to drive innovation in PCB assembly. By investing in robotics, AI-driven analytics, and sustainable manufacturing practices, the company is setting a benchmark for industry standards. To illustrate the anticipated growth and technologies set to influence PCB assembly, here’s a brief overview of key trends:

| Trend | Impact |

|---|---|

| Increased automation | Enhances production speed and reduces labor costs |

| Smart manufacturing | Integrates IoT for real-time monitoring and optimization |

| Green technologies | Promotes environmentally friendly practices in PCB production |

| Modular designs | Facilitates easier upgrades and repairs |

By positioning itself at the forefront of these trends, Bittele is not only enhancing its capabilities but also contributing to the overall growth of the PCB industry in southeast Asia. As the region continues to attract global attention, the role Bittele plays in advancing technology and operational efficiency will be crucial in shaping the future landscape of electronics manufacturing.

to Wrap It Up

Bittele’s launch of PCB assembly capabilities in Malaysia marks a significant step forward in the region’s electronics manufacturing landscape. By establishing a local presence, Bittele not only enhances its operational efficiency but also contributes to malaysia’s growing reputation as a hub for high-quality electronic production. This strategic move is set to benefit both local businesses and international clients by offering faster turnaround times and tailored services. As the demand for custom PCB solutions continues to rise, Bittele’s investment is likely to spur further innovation and development within the Malaysian electronics sector. As we observe these advancements,it will be essential for industry stakeholders to explore the new opportunities presented by such expansions,fostering a more interconnected and competitive marketplace.

![ISWK[Cambridge] Students Bring Glory to Oman at the 2nd Asian Yogasana Sport Championship! – Times of Oman](https://asia-news.biz/wp-content/uploads/2025/05/165927-iswkcambridge-students-bring-glory-to-oman-at-the-2nd-asian-yogasana-sport-championship-times-of-oman-120x86.jpg)